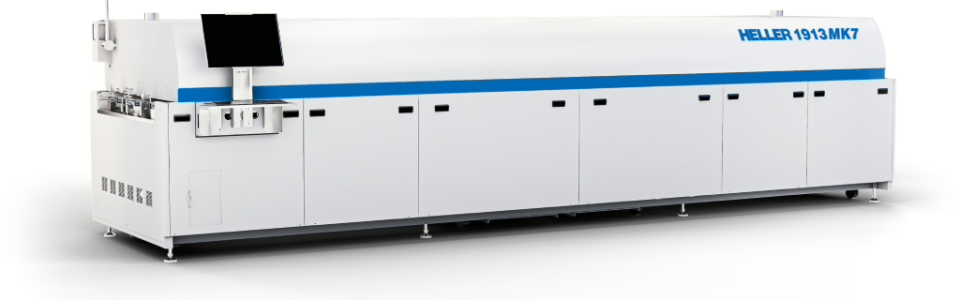

The ISO-certified Heller MK7 reflow oven is a pioneering reflow system with several ground breaking designs

and incorporates all of the customer requests for lower Delta T on the board, reduced nitrogen consumption

and extended product maintenance into a new low height package that makes it easy to see across the

production floor. The MK7 is highly customizable with nitrogen chamber air and vacuum options.

Highlights:

Easy to maintain

Save 10-15% in energy loss

INDUSTRY 4.0 Compatible Reflow Oven

revoluntionary green flux management system that uses catalyst that produces no waste byproduct, and allows

flux removal while reflow soldering oven is running and eliminates the risk of flux clogging.

low delta T on the board

Integrated CPK software at no charge

Specifications

| Oven Length (mm) | 5900 |

| Process Gas Options | Air, Nitrogen |

| Heated Zones | 13 |

| Heated Length (Convection/Total) | 3560 |

| Cool Zones | 3 |

| Max Working Temperature | Standard: 350°C (Option: 400°C) |

| Maximum PCB Width | 55.9cm (22”) (61cm Optional) |

| Cleanroom Option | Down to Class 1000 |

Video