Heller Industries – Software Downloads

Please contact us for downloads

Heller Software Products – Smart System for Smart Manufacturing

- Heller 365 – Heller 365 is an SPC and traceability software enabling operators to monitor the reflow process in real-time to quickly improve product quality and yield, while reducing operational costs. All data are saved in one place which

allows users to look back at previous production and process data. The Heller365 package offer in 3 levels:- Level 1 – (Traceability) Includes logging of all products run, oven parameters including temperature, blower motor speed, power & exhaust, and overall production quality parameters including CpK and Oxygen level.

Track your O2 ppm level by the minute to safeguard your production.

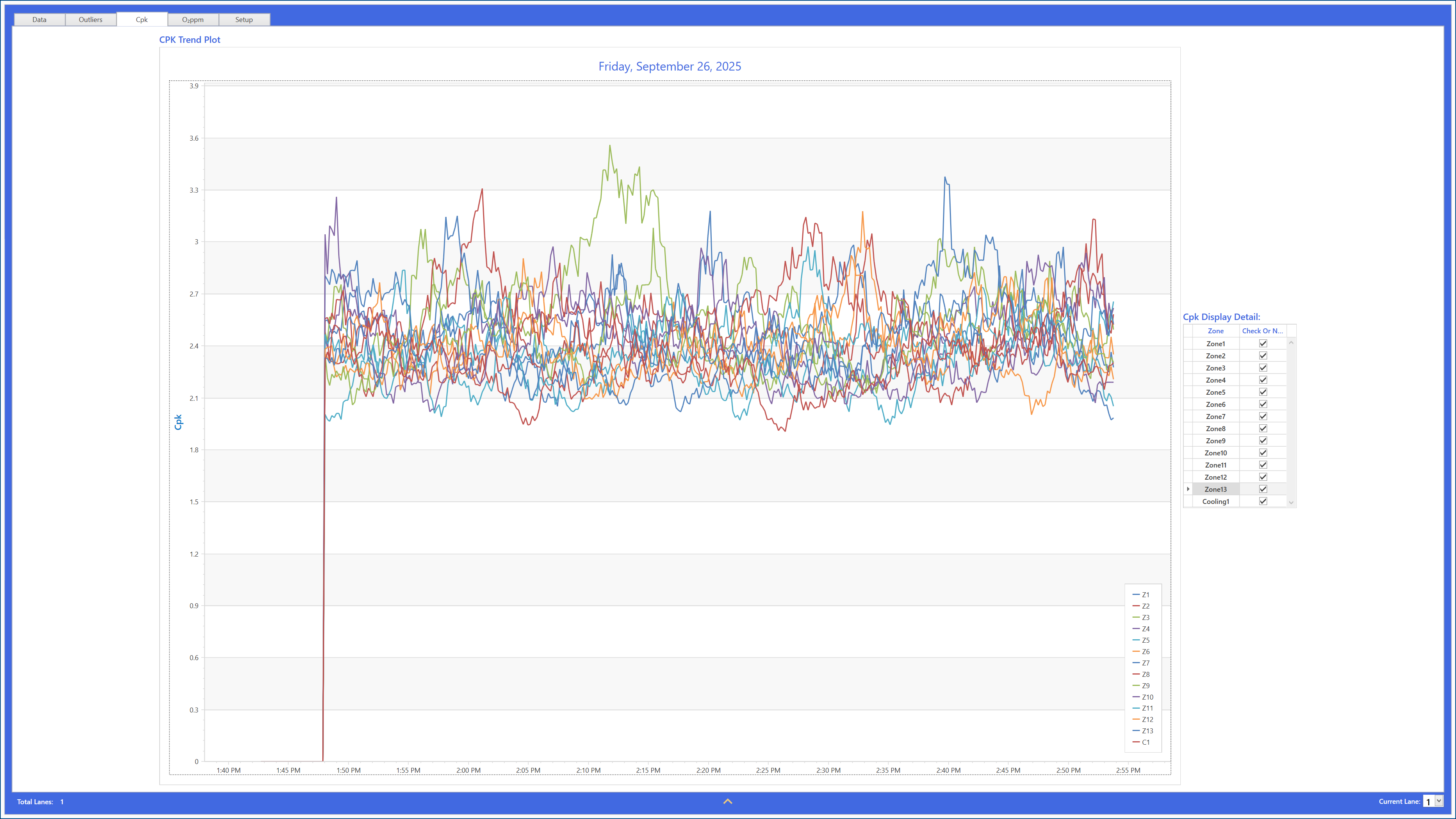

Know the CPK for each of your heating zones to hit your production goals.

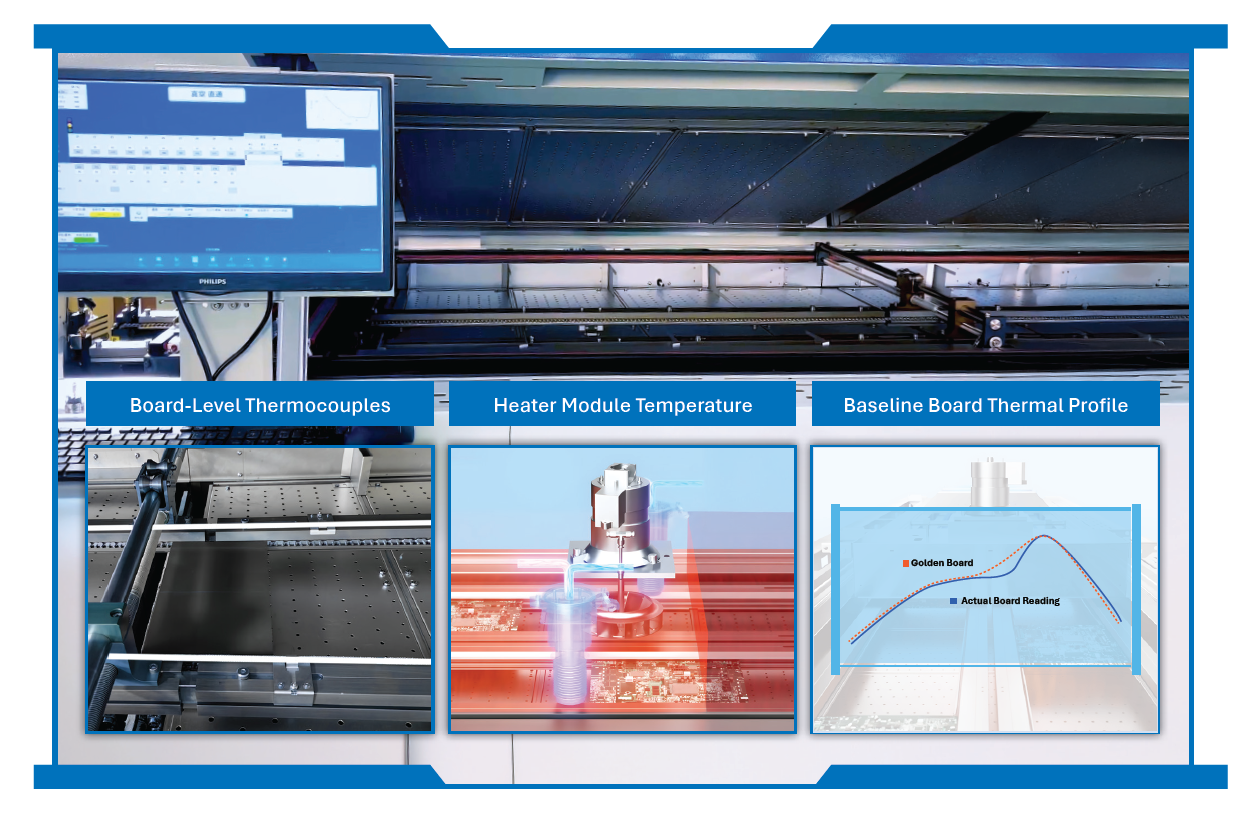

- Level 2 – (Sensor-less Profile Monitoring) Includes Level 1 plus simulated profile monitoring for each board. Heating Module temperature readings are used in scientific calculations to generate profile data for each board. This allows users to have a general idea of product profile.

- Level 3 – (Profile Monitoring with TC) Thermocouples are installed along the rails at board level within each heating and cooling zone, enabling the H365 system to monitor real-time, traceable board-level thermal data. By integrating baseline board profile and temperature readings from heating modules, thermodynamic algorithms are applied to generate board-level thermal profile.

- Level 1 – (Traceability) Includes logging of all products run, oven parameters including temperature, blower motor speed, power & exhaust, and overall production quality parameters including CpK and Oxygen level.

- Industry 4.0 Capable with Heller Interface and Heller Support

- Compatible Interface Standards

- IPC CFX

- Hermes

- SECS/GEM

- ASM

- iLNB

- Fuji Link

Automation with Integrated EFEM

Heller offers EFEM integration for handling both wafers and large glass panels. Dual EFEM and single EFEM with return conveyor configuration options are available.