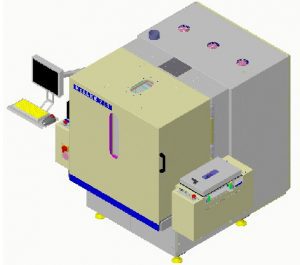

Heller VCO 755 In-line, Continuous Cure, Vertical Format Mini Curing Oven

Increase productivity, improve quality, reduce costs… with vertical format curing solutions from Heller.

In-line, vertical automation of the epoxy cure process produces immediate, significant benefits in three areas:

- In-line automation increases productivity by eliminating the labor needed to load and unload batch ovens.

- It improves process consistency, and therefore quality, by reducing the time and temperature variations caused by the frequent opening of batch oven doors.

- And, as floor allocation costs rise on all factory floors… and particularly in clean rooms… a vertical format oven requires as little as six feet of floorspace for cure cycles as long as four hours

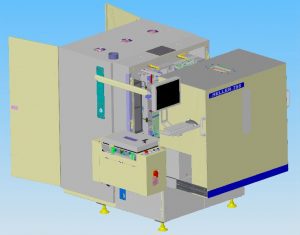

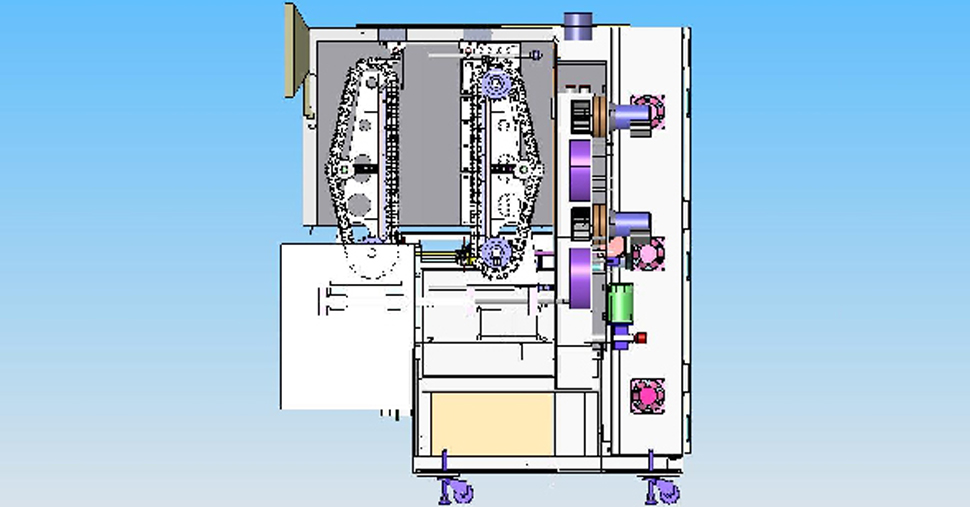

Front Shed

- Sliding Front Shed

- Heat Flow duct

Electrical panel Cabinet

- E-panels

Rear Cabinet

- Driving Motors

- Electrical Parts

Conveyor Cover

- Safety cover

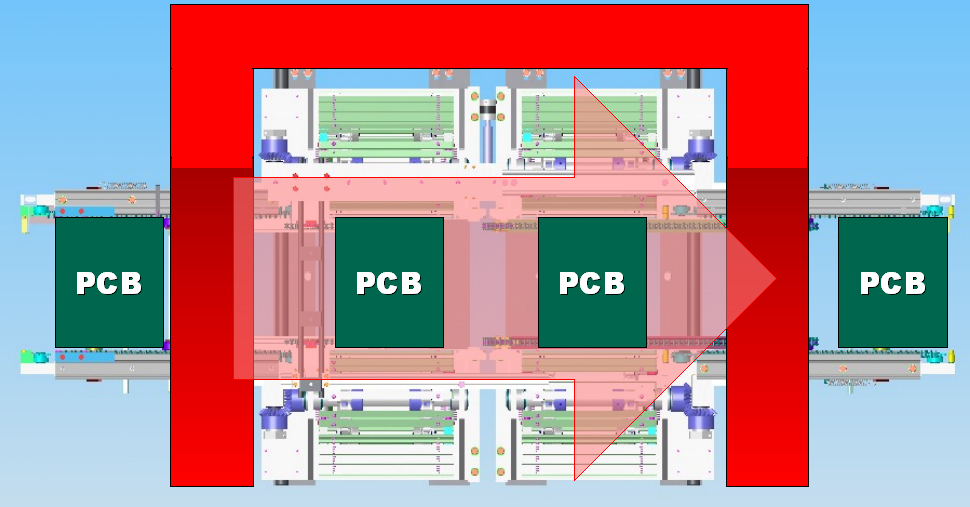

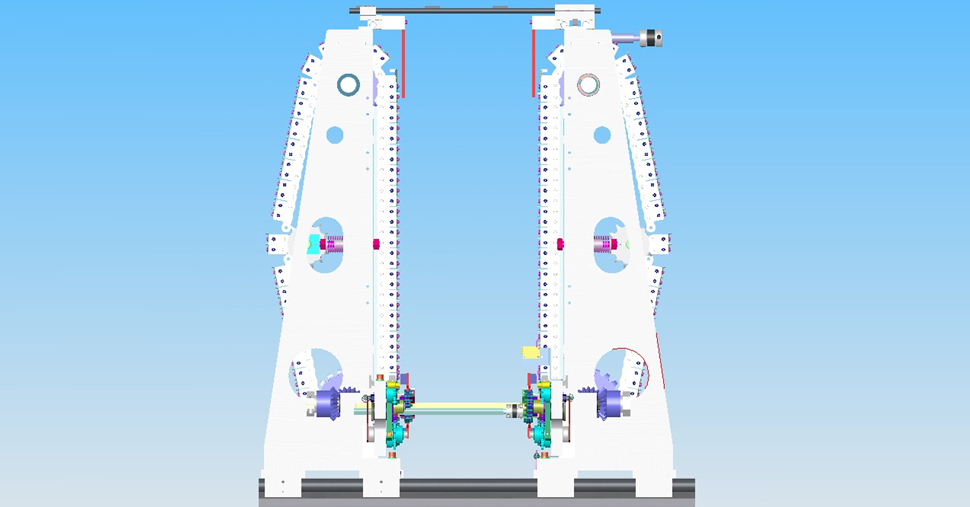

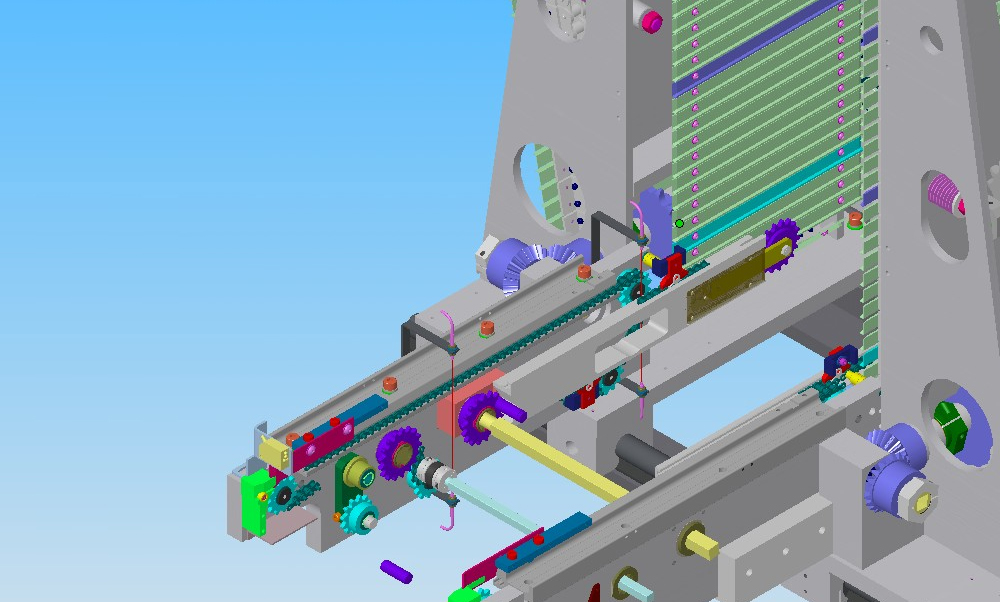

Conveying Mechanism

Board Handling Dimension

- Min Width: 75mm

- Max Width: 250mm

- Length: 250mm

- Shelf Pitch: 19.05mm

- Total carriage: 50 boards

Miscellaneous

- Computer Controlled width

- Entrance Conveyor

- Up-Conveyor

- Down-Conveyor

- Exit-Conveyor

- Bottom Shuttle

- Top Shuttle

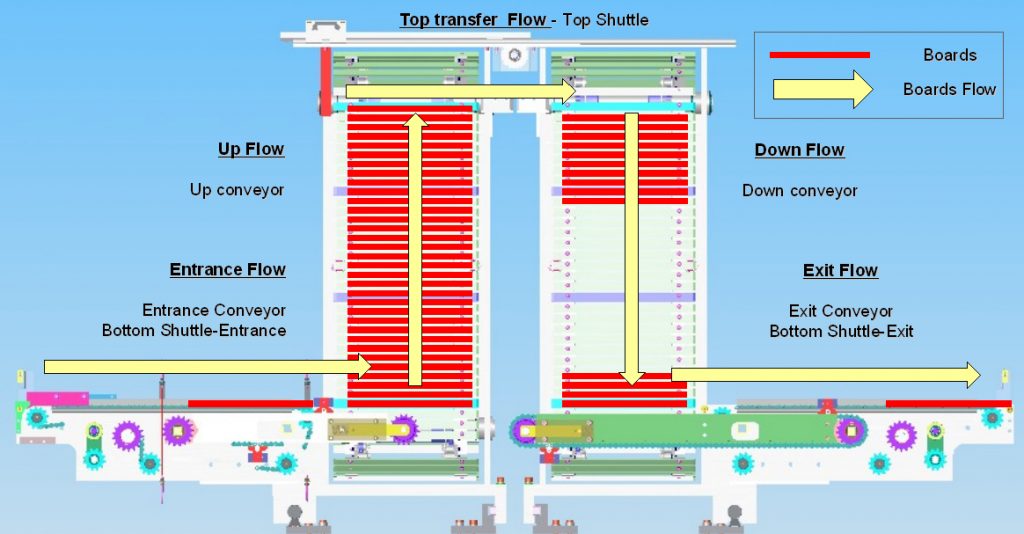

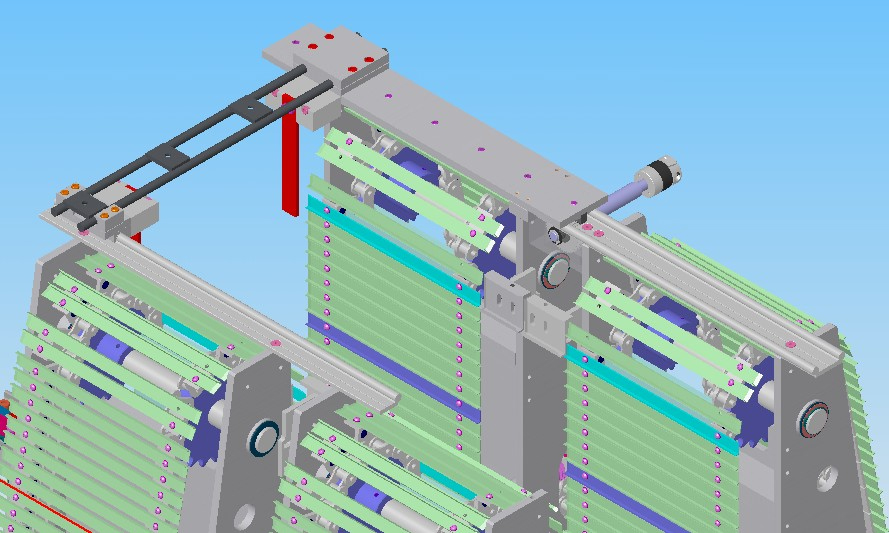

Top Shuttle

- Min Width: 75mm

- Max Width: 250mm

- Rack & Pinion drive

Miscellaneous

- Queuing stage

- Transferring a board from Up-conveyor to Down-Conveyor

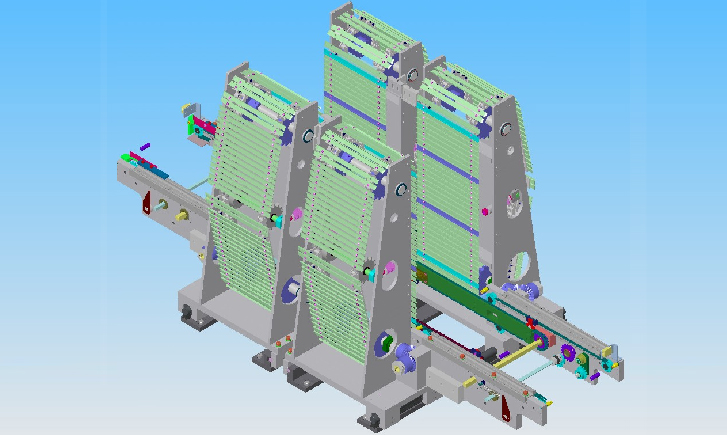

Entrance Conveyor & Bottom Shuttle

Entrance Conveyor

- Min Width: 75mm

- Max Width: 250mm

- #35 Chain drive

Bottom Shuttle – Entrance

- #35 Chain drive

Miscellaneous

- Queuing stage

- SMEMA I/F

- #35 Chain drive

- (3) Board detect sensors