Tips for Setting Up an Optimized Vacuum Profile when Using Vacuum Assisted Reflow

With today’s increasing demands on device reliability, vacuum reflow soldering is now seen as the industry’s choice for solder void mitigation. While vacuum reflow soldering works very similar to normal reflow soldering, there are a few key things users should be aware of.

An Effective Vacuum Assisted Reflow Process for Void Removal

- Certain components have limits to the pressure that can be exposed to. Be aware of any such limitations with the components you plan to vacuum reflow to avoid any possible damage when exposed to high levels of vacuum.

- Higher vacuum levels tend to produce lower void rates but are associated with longer vacuum cycle times.

- Longer dwell times can also help with reducing void rates. There is a point of diminishing returns, however, where longer dwell time ceases to help. Also, dwell times should not be set so long to where solder fluxes become completely depleted and solder dewetting can occur.

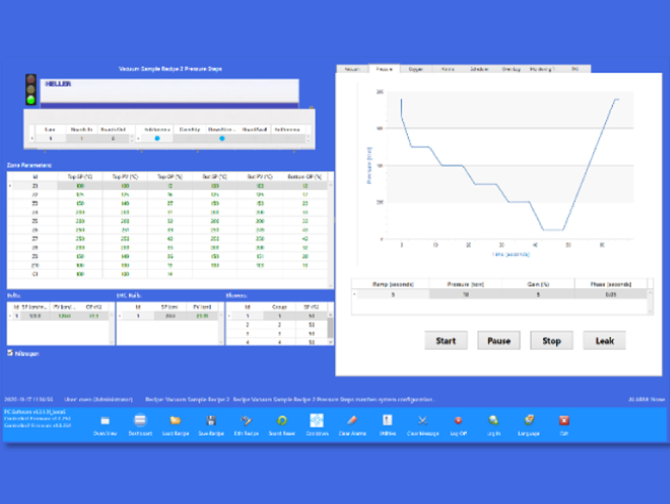

- Fast pump-down rates can perform better than slower pump-down rates for void removal, but it comes with a higher risk. If pressure is reduced too quickly, voids can be pulled out of the joint violently causing solder to splash across the board, and even shifting the component. Slower pump-down rates can be achieved with a multi-step profile. Heller ovens are closed-loop controlled and allow up to 5 pump-down and 2 refill steps.

Vacuum Assisted Reflow Profile Development

Developing the correct vacuum profile (pump-down rates, vacuum level, dwell times) can be a balancing act that may take a few iterations to optimize. X-ray void analysis should be performed

after each iteration to ensure the correct progress is made towards optimizing your vacuum profile.