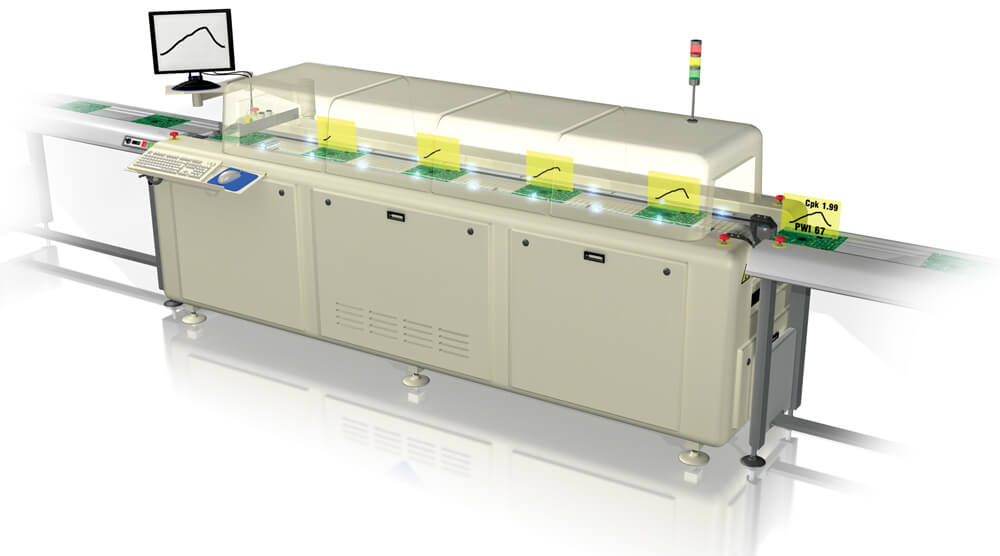

Auto-Focus Power™ Profiling Software – Ultra Fast Reflow Oven Setup & Changeover

Heller ovens offer billions of alternative setups to make sure that various electronic assemblies are reflowed in spec. To utilize this capability & enable extreme fast reflow oven setup and changeover we offer the optional KIC Auto-Focus Power software.

Auto-Focus Power™ employs an intelligent database that learns thermal properties of Heller ovens as they relate to each unique assembly & process window. When starting new assembly production users simply input product length, width and weight along with the required process window. Auto-Focus will within seconds display the recommended oven recipe, prior to running a profile. A single click downloads the new recipe to the oven.

The Auto-Focus database ships empty but starts making oven setup recommendations after a dozen profile runs. KIC’s powerful profiling software reduces production downtime, rework and scrap while improving consistent performance.

Smart Oven Technology

All Heller reflow ovens are optionally supplied with smart oven technologies from KIC.

The KIC RPI automatically verifies in real-time that each and every assembly is processed in spec. Process data for each manufactured PCB is automatically saved and can be retrieved for traceability purposes. Data can be shared via the factory local area network with any authorized person or with an MES system. KIC’s profiling optimization software identifies optimal energy efficient setups while reducing or even eliminating reflow oven changeover time. Process transparency lowers multiple risks of defects while providing consistent quality regardless of application, personnel, production line and even geographical location. Increased reflow oven equipment utilization leads to lower cost + faster shipments.

Learn more about Auto-Focus Power™ Profiling Software on the KIC’s website »»