Reflow Oven Flux Removal System – Low Temperature Catalyst

- Clean flux removal – No liquid or solid waste generated.

- No harmful exhaust.

- Does not require additional power, reduces overall power use.

- Catalyst reaction reduces O 2 PPMs, reducing nitrogen use.

- Doubles PM interval

- No impact to thermal profile

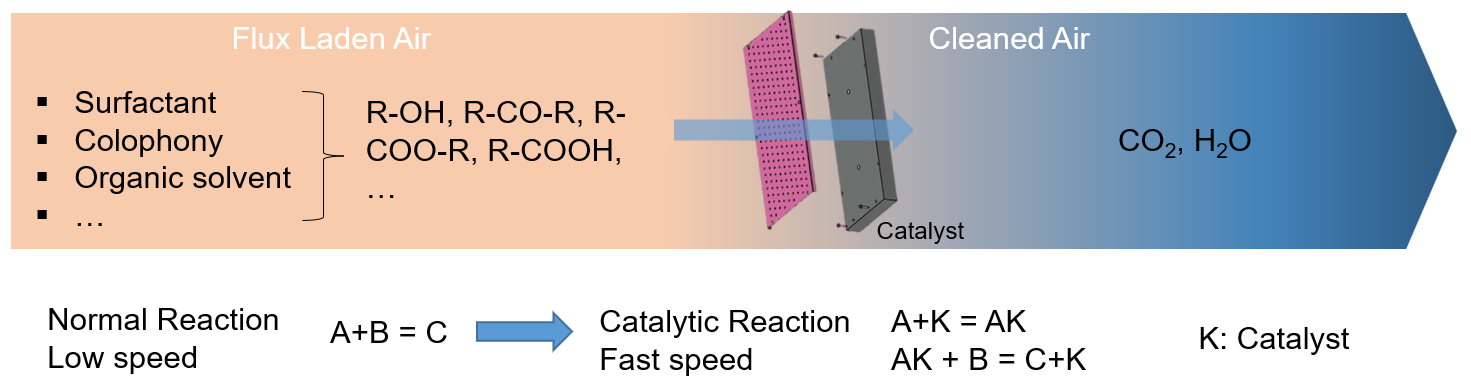

How it Works

The reflow oven flux removal system from Heller is a low temperature integrated catalyst installed in the heat modules. The catalyst provides a large surface area for reacting with flux, decomposes it into harmless CO 2 and H 2 O. The effective temperature range for the catalyst is ~ 200°C – 250°C.

A Green Solution for Flux Removal

Unlike alternative reflow oven flux removal methods, the low temperature catalyst requires no additional power to operate. The catalyst reaction has the added benefit of reducing Oxygen within the oven, driving less Nitrogen usage to achieve PPM levels. The low temperature catalyst system also generates no harmful exhaust and produces no liquid or solid waste. With lower power and Nitrogen use, and no waste byproducts generated, the low temperature catalyst is truly a green solution for flux removal.

Cost of Ownership Savings

The low temperature catalyst saves money in multiple ways:

Power Savings – The catalyst does not require additional power or cooling like other flux removal systems. No additional heat is generated saving additional power in AC use.

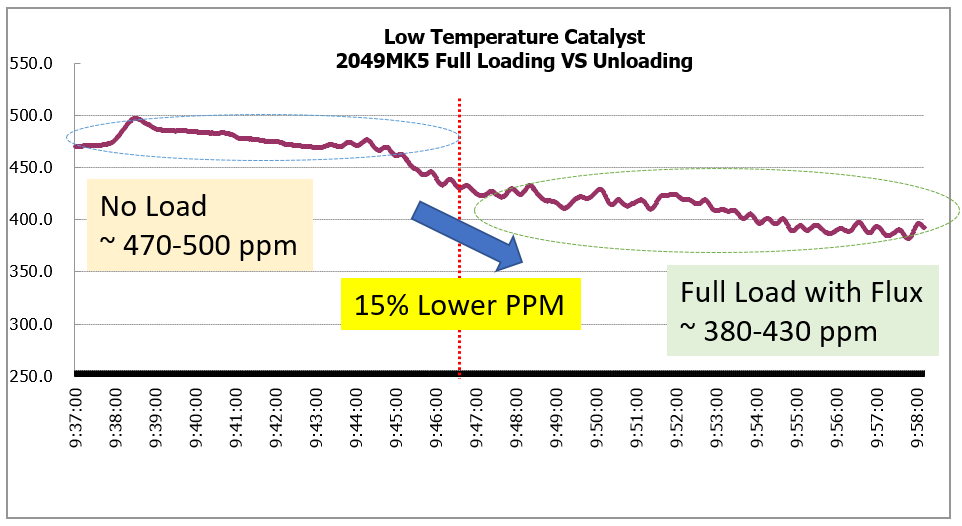

Nitrogen Savings – The catalyst reaction reduces overall O 2 in the oven reducing Nitrogen use. The extent of this savings depends on the flux load and target PPM level.

PM Savings – The catalyst reduces flux buildup within the oven. This can double the overall PM interval, and reduce PM related downtime.

Field Upgradeable

The low temperature catalyst is field upgradeable and is compatible with most MK3, MK5 and MK7 reflow ovens. The cost of upgrading 3 modules with catalyst typically pays for itself in ~1 year from electricity and Nitrogen savings alone!