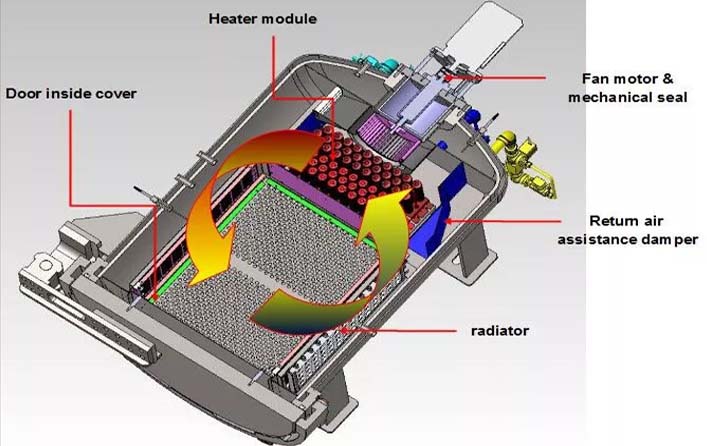

- PCO pressurizes air into a rigid vessel and heats & cools with forced convection.

- Heaters, heat exchangers and blowers are internal to the pressure vessel.

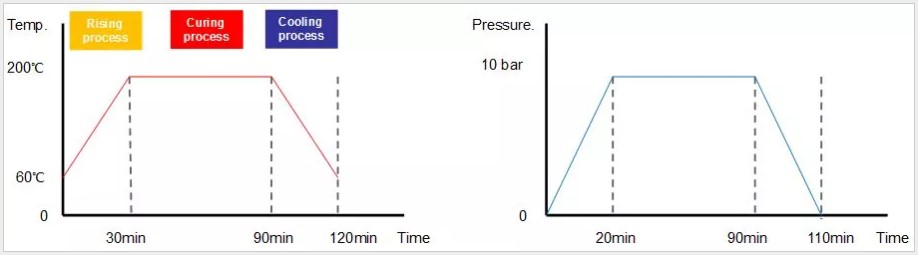

- When the curing process is complete, the Pressure Curing Ovens automatically relieves its pressure to 1atm and cools.

Process Specification:

- Process time: Generally 120 min or User’s spec

- Operating temp: 60oC ~ 200oC

- Maximum temp: 220oC

- Operating pressure: 1 bar – 10 bar

- Capacity: 24 Magazines (typical)

- Cooling method: PCW (17oC – 23oC)

- Cooling water pressure: 25 – 40 psi

Pressure Cure Applications:

- Composite Forming for the printing industry

- Die Attach Curing

- Wafer Laminating

- Thermal Compress Bonding

- Underfill Curing

- Via Filling

- Film & Tape Bonding

Manual loading batch Pressure Curing Oven for magazines

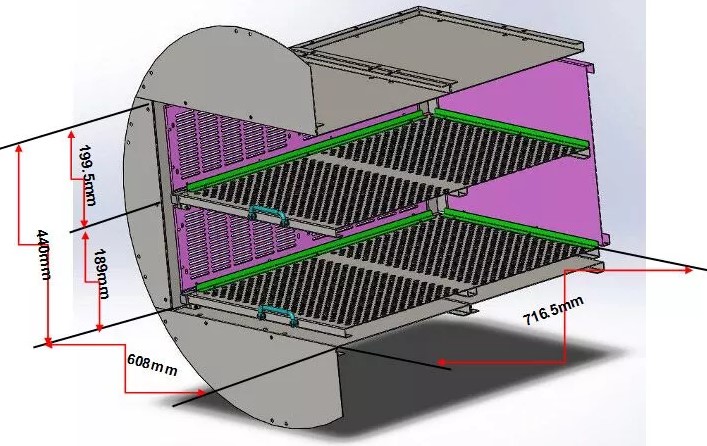

- Oven Size (mm): 2,200[L] x 1,700[W] x 1,700[H]

- Chamber Usable Area (mm): 716.5[L] x 608[W] x 440[H]

- Max Operating Pressure: 10 Bar (145 psi)

- Max Operating Temperature: 200⁰ C

- Typical Capacity: 24 Magazines

- Nitrogen Enabled (option)

- Up to Cleanroom Class 100 (option)

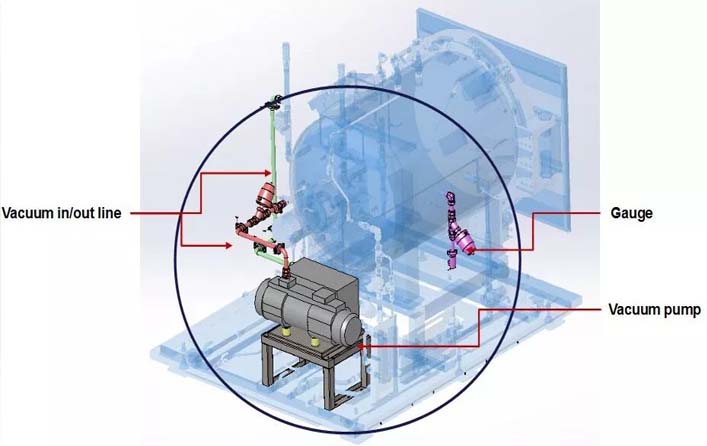

- Vacuum down to 10 Torr (option)

- Manual Loading