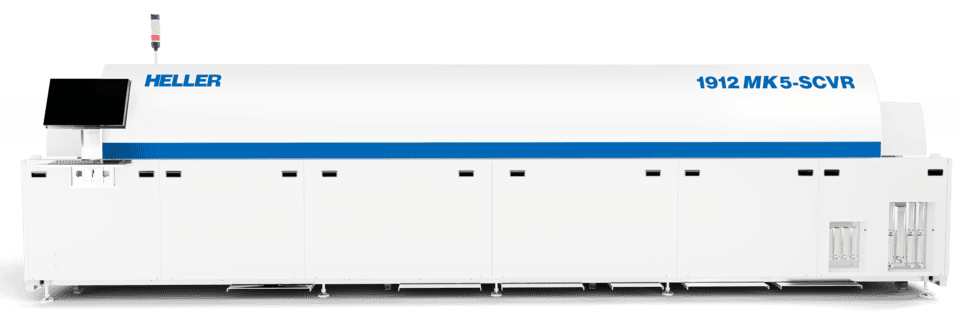

1912MK5-Short Cycle Vacuum Reflow Oven

The 1912 Short-Cycle Vacuum Reflow Oven is highly recommended for high temperature semiconductor applications, up to 450 °C degrees, such as for IGBT power module, silicon carbide, Die Attach, and Clip Attach. The small size of this oven also makes it ideal to fit in a clean room and saves space.

Dimensions

| Overall Oven Dimensions | 620 cm (L) × 175 cm (W) |

| Typical Net Weight (Oven / Pump) | 3800 kg / 500 kg |

Electric Supply

| Typical Power Consumption (Oven / Pump) | 10 ~ 16 / 4 ~ 7 kW @ 480 V |

Process Atmosphere

| Typical Nitrogen Consumption | 150 ~ 400 SLPM (9 ~24 m³/hr)** |

| Minimum PPM Oxygen | <=25 PPM |

Temperature Control

| Temperature Controller Resolution | ± 0.1 °C |

| Typical Cross-Width Temperature Uniformity | ± 2.0 °C *** |

| Temperature Range | 60-350 °C (60-450 °C Optional) |

Forced Convection Heating & Cooling Zones

| Heating Zones | 11 |

| Heated Tunnel Length (Convection/Total) | 305 cm / 360 cm |

| Cooling Zones | 4 |

| Cooling Tunnel Length | 137 cm |

Vacuum System Option

| IR Heater Temperature Range | 60-400 °C (60-480 °C Optional) |

| Minimum Vacuum Pressure | 2 mbar (1.5 Torr) |

| Vacuum Speed / Pressure Control | 5-Step Closed Loop Speed / Pressure Control & Dual Stage Refill |

| Vacuum Pump | 300m³/hr High-Capacity Rotary Vane Pump |

Edge Hold Conveyor System Option

| Maximum PCB Size (L × W) | 35 cm × 45 cm |

| Conveyor Speed Range | 1-800 cm/min |

| Conveyor Direction | Left to Right (Right to Left Optional) |

| Center Board Support System | / |

Side Chain Belt Conveyor System Option

| Effective Belt Width | 45 cm |

Contact sales for more information about our short cycle vacuum reflow ovens

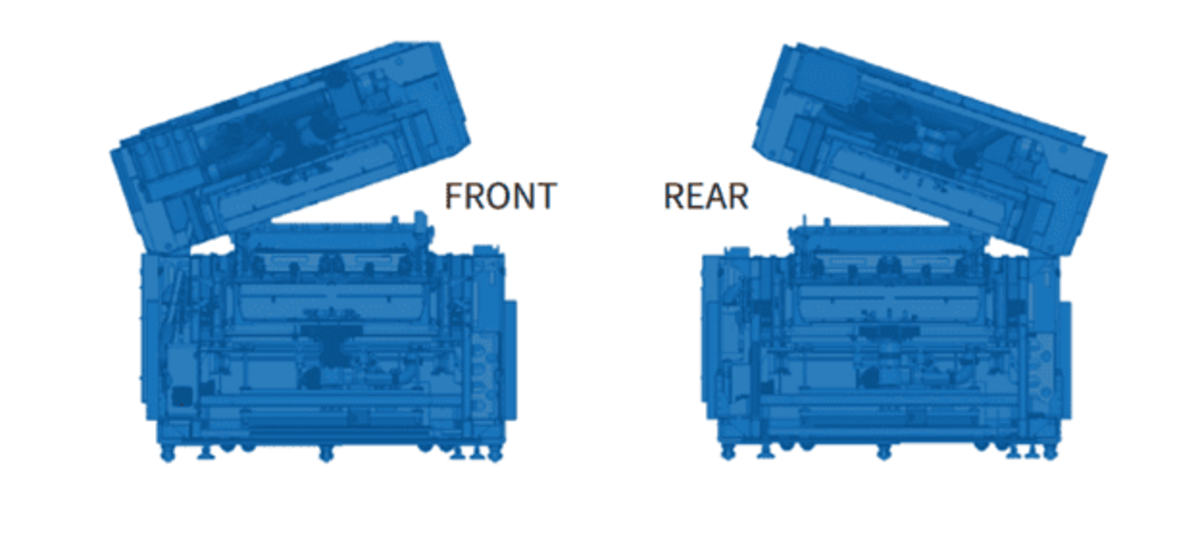

Looking for flexibility in upgrades, cleaning efficiency, and easy maintenance? We’ve got you covered.

Heller’s Short-Cycle Vacuum Oven features a modular design with open architecture, allowing easy upgrades and additional features for enhanced capabilities with ease. A reserved MES interface enables seamless digital factory integration. The oven top shell can be opened from either the front or rear side to maximize access during maintenance and significantly improve cleaning efficiency, serviceability, and operational safety, especially for ultra-wide tracks.