Short-Cycle Vacuum Reflow Oven

Minimal Vacuum Reflow Oven Cycle Time for Maximized Throughput

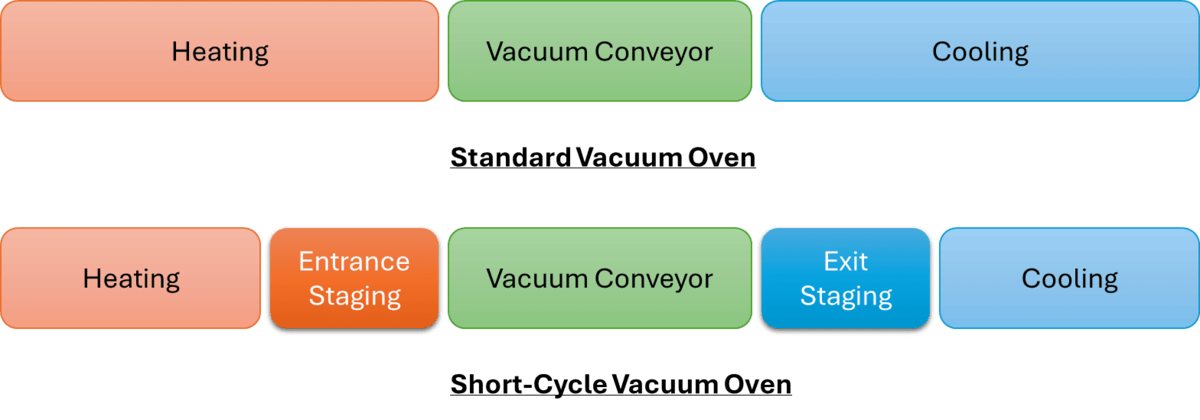

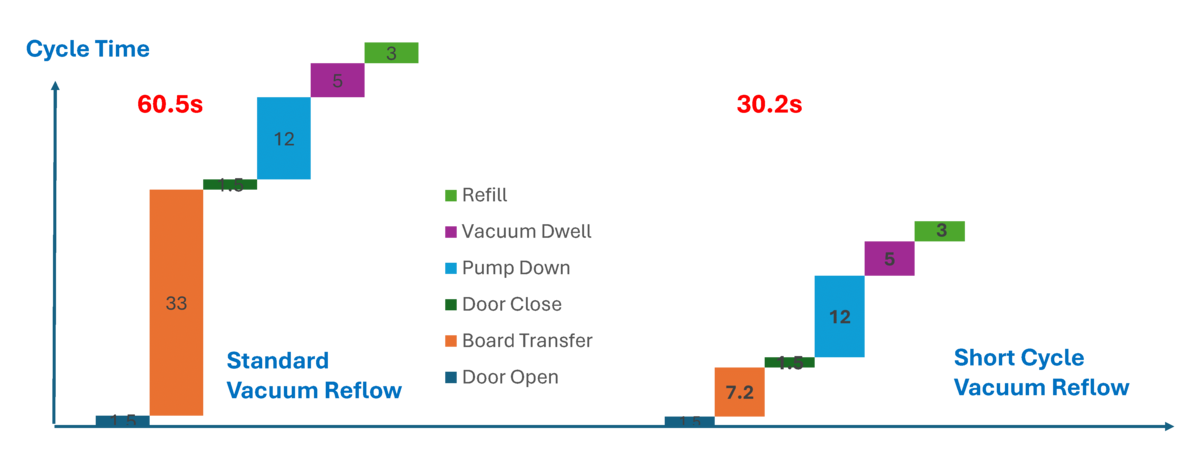

The cycle time of the vacuum oven is determined by vacuum time and transfer time in and out of the vacuum chamber. Since reducing the vacuum time may affect void rate. The most effective way to shorten the oven cycle time without affecting production quality is to reduce the transfer time. Heller’s Short-Cycle Vacuum Oven achieves this by innovating a multi-stage conveyor system, which speeds up the transfer of the board before and after the vacuum chamber.

Patent number: CN222728852U

Patent name: A multi-stage speed-adjustable transmission mechanism

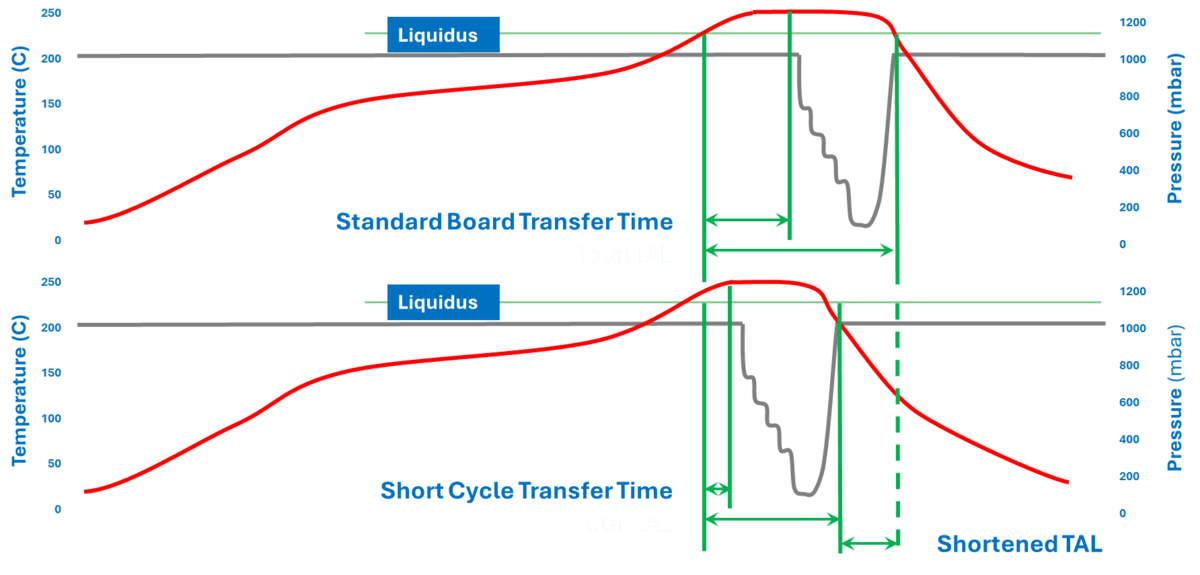

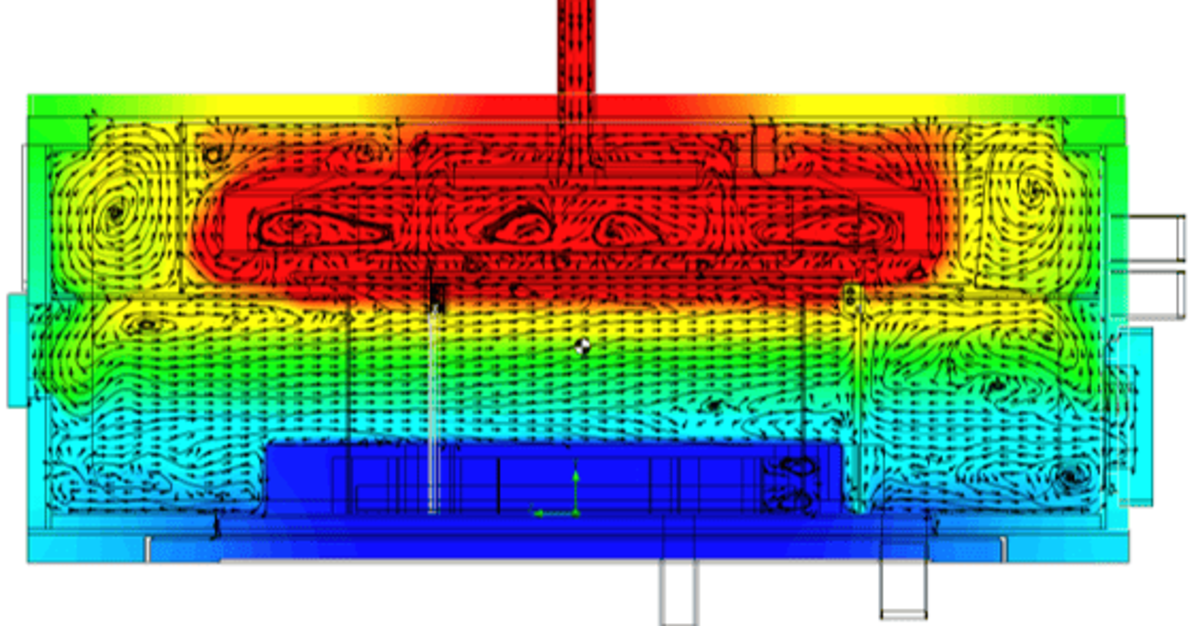

Shortened Vacuum Reflow Oven Time Above Liquidus

The vacuum chamber contains 3 infrared panels capable of heating the board at the same time as the vacuum application, which allows the solder paste to reach its recommended maximum temperature during vacuum chamber. Together with the shortened board transfer time entering the vacuum chamber, the total time above liquidus (TAL) can be optimized to match the solder paste recommendation.

Smart and Consistent Temperature Control Vacuum Reflow Oven:

Our Short-Cycle Vacuum Reflow Oven is equipped with real-time and smart temperature control, which allows users to accurately control temperature on the PCB board, and make granular adjustment to the thermal recipe with ±0.5°C accuracy. By slowing down the cooling conveyor, the cooling zone dwell time can be extended to reduce board exit temperature.

Short Cycle Vacuum Reflow Oven Applications:

- High-reliability RF component Vacuum soldering

- Mini LED/Micro LED Mass Reflow

- Highly Reliable SMT

- Automotive-grade IGBT/SiC power module packaging

- High-density interconnect soldering

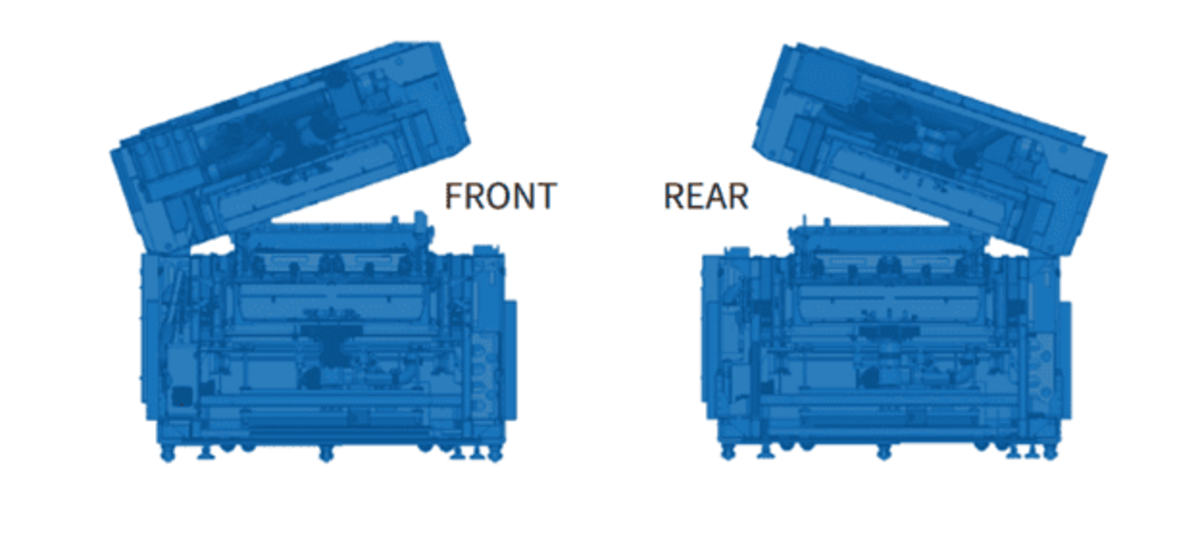

Looking for flexibility in upgrades, cleaning efficiency, and easy maintenance? We’ve got you covered.

The Short-Cycle Vacuum Reflow Oven features a modular design with open architecture, allowing easy upgrades and additional features for enhanced capabilities with ease. A reserved MES interface enables

seamless digital factory integration. The oven top shell can be opened from either the front or rear side to maximize access during maintenance and significantly improve cleaning efficiency, serviceability, and operational safety, especially for ultra-wide tracks.

Learn why the technology of Heller’s Vacuum Reflow Soldering Ovens lead the industry.